Measurement specifications for the latest resistors

Measurement Specifications for the Latest Resistors

I. Introduction

Resistors are fundamental components in electronic circuits, serving the essential function of limiting current flow and dividing voltages. They are ubiquitous in various applications, from simple household devices to complex industrial machinery. Understanding the measurement specifications of resistors is crucial for engineers and designers, as these specifications directly impact the performance and reliability of electronic systems. This blog post aims to provide a comprehensive overview of the latest measurement specifications for resistors, exploring their types, key specifications, measurement techniques, standards, recent technological advances, and applications.

II. Types of Resistors

Resistors can be broadly categorized into three main types: fixed, variable, and specialty resistors.

A. Fixed Resistors

1. **Carbon Composition Resistors**: These resistors are made from a mixture of carbon particles and a binding resin. They are known for their high energy absorption and ability to withstand high temperatures, but they have a relatively high tolerance and are less stable over time.

2. **Metal Film Resistors**: Constructed from a thin film of metal, these resistors offer better stability and lower noise compared to carbon composition resistors. They are widely used in precision applications due to their tight tolerance levels.

3. **Wirewound Resistors**: Made by winding a metal wire around a ceramic or fiberglass core, wirewound resistors can handle high power ratings and are often used in applications requiring high precision and stability.

B. Variable Resistors

1. **Potentiometers**: These are adjustable resistors that allow users to change resistance values manually. They are commonly used in volume controls and other applications where variable resistance is needed.

2. **Rheostats**: Similar to potentiometers, rheostats are used to control current. However, they are typically used in higher power applications and can handle larger currents.

C. Specialty Resistors

1. **Thermistors**: These temperature-sensitive resistors change resistance with temperature variations. They are widely used in temperature sensing and control applications.

2. **Photoresistors**: Also known as light-dependent resistors (LDRs), these components change resistance based on light exposure. They are commonly used in light-sensing applications, such as automatic lighting systems.

III. Key Measurement Specifications

Understanding the key measurement specifications of resistors is essential for selecting the right component for a specific application.

A. Resistance Value

1. **Definition and Units (Ohms)**: The resistance value indicates how much a resistor opposes the flow of electric current, measured in ohms (Ω).

2. **Tolerance Levels**: Tolerance refers to the allowable deviation from the specified resistance value. Common tolerance levels include ±1%, ±5%, and ±10%, with lower tolerance levels indicating higher precision.

B. Power Rating

1. **Definition and Units (Watts)**: The power rating indicates the maximum amount of power a resistor can dissipate without being damaged, measured in watts (W).

2. **Importance of Power Rating in Circuit Design**: Selecting a resistor with an appropriate power rating is crucial to prevent overheating and potential failure in a circuit.

C. Temperature Coefficient

1. **Definition and Significance**: The temperature coefficient measures how much a resistor's resistance changes with temperature, typically expressed in parts per million per degree Celsius (ppm/°C).

2. **Impact on Performance in Varying Temperatures**: Resistors with a low temperature coefficient are preferred in precision applications, as they maintain stable resistance values across a range of temperatures.

D. Voltage Rating

1. **Definition and Implications**: The voltage rating indicates the maximum voltage that can be applied across a resistor without causing breakdown or failure.

2. **Breakdown Voltage Considerations**: Exceeding the voltage rating can lead to resistor failure, making it essential to consider this specification in circuit design.

IV. Measurement Techniques

Accurate measurement of resistor specifications is vital for ensuring optimal performance in electronic circuits.

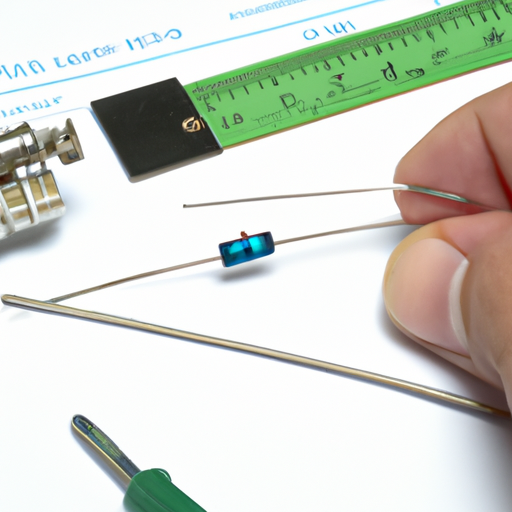

A. Multimeter Usage

1. **How to Measure Resistance**: A multimeter can be used to measure resistance by connecting the probes to either end of the resistor and selecting the resistance measurement mode.

2. **Importance of Calibration**: Regular calibration of multimeters is essential to ensure accurate measurements, as uncalibrated devices can lead to erroneous readings.

B. LCR Meter

1. **Measuring Inductance, Capacitance, and Resistance**: An LCR meter is a specialized instrument that can measure inductance, capacitance, and resistance, providing a comprehensive view of a component's electrical characteristics.

2. **Advantages of Using an LCR Meter**: LCR meters offer higher accuracy and can measure components under various frequencies, making them ideal for testing resistors in different applications.

C. Oscilloscope

1. **Measuring Resistance in AC Circuits**: An oscilloscope can be used to analyze the behavior of resistors in AC circuits by observing voltage and current waveforms.

2. **Analyzing Waveform Effects on Resistors**: By examining how resistors respond to different waveforms, engineers can gain insights into their performance in real-world applications.

V. Standards and Compliance

Adhering to industry standards and guidelines is crucial for ensuring the quality and reliability of resistors.

A. International Electrotechnical Commission (IEC) Standards

The IEC sets international standards for electrical and electronic components, including resistors, ensuring consistency and safety across the industry.

B. American National Standards Institute (ANSI) Guidelines

ANSI provides guidelines for the manufacturing and testing of resistors, promoting best practices and quality assurance in the industry.

C. Importance of Compliance in Manufacturing and Testing

Compliance with these standards is essential for manufacturers to ensure their products meet safety and performance requirements, ultimately protecting consumers and enhancing product reliability.

VI. Recent Advances in Resistor Technology

The field of resistor technology has seen significant advancements in recent years, driven by the demand for higher precision and performance.

A. Innovations in Materials (e.g., Thin-Film Technology)

Thin-film technology has emerged as a popular method for producing resistors with enhanced precision and stability. These resistors are made by depositing a thin layer of resistive material onto a substrate, resulting in improved performance characteristics.

B. Enhanced Precision Resistors

Recent developments have led to the creation of precision resistors with tighter tolerances and lower temperature coefficients, making them ideal for high-performance applications in telecommunications, aerospace, and medical devices.

C. Smart Resistors and Their Measurement Capabilities

The advent of smart resistors, equipped with integrated sensors and communication capabilities, allows for real-time monitoring and measurement of resistance values. This technology is particularly beneficial in applications requiring dynamic adjustments based on environmental conditions.

VII. Applications of Resistors

Resistors play a vital role in various industries, each with unique requirements and applications.

A. Consumer Electronics

In consumer electronics, resistors are used in devices such as smartphones, televisions, and audio equipment, where they help manage power and signal integrity.

B. Industrial Applications

In industrial settings, resistors are essential for controlling machinery, monitoring systems, and ensuring safety in electrical circuits.

C. Automotive and Aerospace

Resistors are critical components in automotive and aerospace applications, where they contribute to the reliability and safety of electronic systems, including navigation, communication, and control systems.

D. Medical Devices

In the medical field, precision resistors are used in diagnostic equipment, monitoring devices, and therapeutic systems, where accuracy and reliability are paramount.

VIII. Conclusion

In conclusion, understanding the measurement specifications for the latest resistors is essential for engineers and designers in the electronics industry. As technology continues to advance, the demand for high-precision, reliable resistors will only grow. By staying informed about the latest developments and adhering to industry standards, professionals can ensure the successful integration of resistors into their designs, ultimately contributing to the advancement of modern electronics.

IX. References

1. Academic journals and articles on resistor technology and measurement.

2. International Electrotechnical Commission (IEC) standards documentation.

3. American National Standards Institute (ANSI) guidelines and publications.

4. Manufacturer specifications and datasheets for various resistor types.

This blog post provides a comprehensive overview of the measurement specifications for the latest resistors, ensuring that readers gain a thorough understanding of this critical component in electronic design.