电阻器和电阻有哪些热门型号?

System

Sep 21

0

电阻器的主要型号和类型

I. 引言

电阻器是电子电路的基本组成部分,其关键作用是控制电流的流动。通过提供电阻,它们有助于管理电压水平,保护敏感元件,并确保电路按预期运行。本文将探讨各种类型的电阻器,它们的特性以及流行的型号,为理解这些电子电路中不可或缺的组件提供全面的了解。

II. 电阻器的基本概念

A. 什么是电阻?

电阻是电路中对电流流动的阻碍的度量。它以欧姆(Ω)为单位量化,是材料的固有属性。电阻越高,给定电压下的电流流动越少。

B. 欧姆定律

欧姆定律是电子学中的一个关键原则,它关联了电路中的电压(V)、电流(I)和电阻(R)。它表示为:

\[ V = I \times R \]

这个方程说明,电阻器两端的电压与流经它的电流成正比,电阻作为比例常数。

C. 根据功能分类的电阻器类型

电阻器可以根据其功能分为两大类:固定电阻器,其电阻值是恒定的;可变电阻器,允许调整电阻值。

III. 常见类型的电阻器

A. 固定电阻器

固定电阻器保持恒定的电阻值,广泛应用于各种场合。一些常见类型包括:

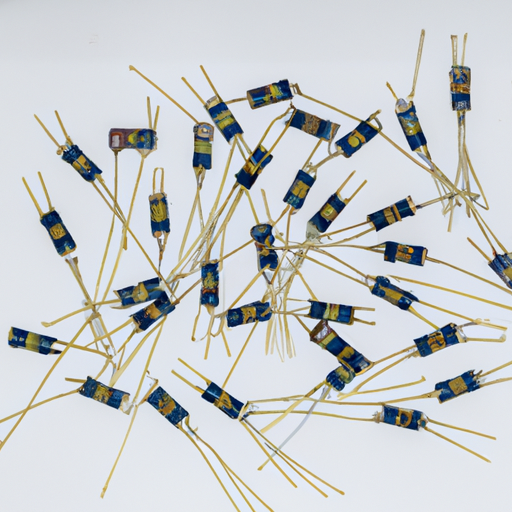

1. **碳组合电阻器**:由碳和粘合材料混合制成,这些电阻器以高能量吸收和能承受高电压脉冲而闻名,常用于需要高脉冲负载的应用中。

2. **金属膜电阻器**:通过在陶瓷基板上沉积一层薄金属制成。它们提供高精度和稳定性,适用于音频设备、精密电路等。

3. **碳膜电阻器**:与金属膜电阻器相似,通过沉积一层薄碳制成。它们提供比碳组合电阻器更好的性能,常用于一般性应用。

4. **线绕电阻器**:通过在陶瓷或玻璃纤维芯上绕制金属线制成,能处理高功率水平,常用于电源和工业应用中。